Kubuda kweiyo electrophoretic coating process ndeye electrophoretic coating process, iyo inoisa kumberi kwepamusoro uye yepamusoro zvinodiwa zvemhando yezvigadzirwa zvemotokari. Kuchengetedzeka kwepamusoro, kuchengetedzwa kwakakwirira kwezvakatipoteredza uye hunhu hwakasiyana-siyana hwemotokari hunotaridza izvo zviri kuwedzera zvakakwirira zvinodiwa tekinoroji yekudzivirira kwepamusoro yezvibatiso. Saka, ndeapi maitiro ekushandisa e electrophoretic coating?

Electrophoretic coating ine zvinotevera maitiro:

(1) Maitiro ekuputira ari nyore kugadzira uye otomatiki, izvo zvisingangodzikisi kusimba kwevashandi asiwo zvinovandudza zvakanyanya kugadzirwa kwevashandi. Nekuvandudzwa kweindasitiri yemotokari, tekinoroji uye midziyo yekupfeka mota, kunyanya iyo mota yekupfeka, yakashandiswa nekukurumidza munyika yedu.

Parizvino, nhanho yemidziyo yekupfekedza yakaiswa munyika yangu yakagadziridzwa zvakanyanya. Mune ramangwana, nekushandiswa kwezvipfeko zvekudzivirira kwezvakatipoteredza zvakadai semvura-based coatings uye poda coatings, nyika yangu yekupfekedza tekinoroji level inowanzosvika padanho repamusoro renyika. Zvinoenderana nedata kubva kumugadziri wemotokari, kugona kwemotokari primer kwakawedzera ne450% mushure mekutanga dip coating yachinjwa kuita electrophoretic coating.

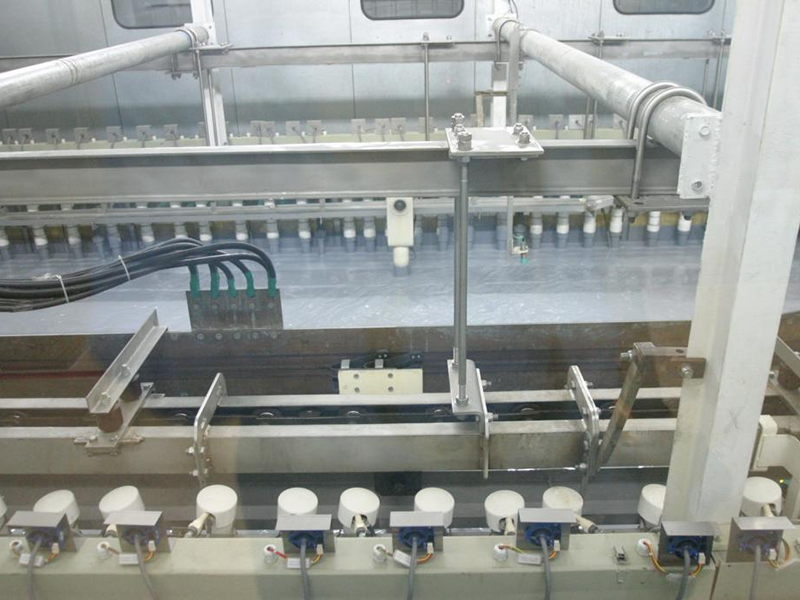

(2) Nekuda kwemunda wemagetsi (JN YN), iyo electrophoretic coating ine chimiro chakaoma, saka inokodzera maworkpieces ane maumbirwo akaomarara, mipendero, makona, uye maburi, akadai sewelded parts, nezvimwewo, izvo zvinogona kugadzirisa simba uye kutonga ukobvu hwefirimu kune imwe nhanho.

Semuenzaniso, mumikova yewaya dzewelding munzvimbo, mukati nekunze kwebhokisi kunogona kuwana firimu rependi rakafanana, uye kushorwa kwekuora uye kushomeka kwekudzivirira kunovandudzwawo zvakanyanya.

(3) Zvikamu zvepolymer zvinopomerwa zvakaiswa pasi pechiito chemunda wemagetsi, saka kudzivirira kwemvura kwefirimu ye electrophoretic coating yakanaka kwazvo, uye kunamatira kwefirimu yepende yakasimba kudarika dzimwe nzira.

(4) Iyo yependi yemvura inoshandiswa mu electrophoretic coating ine yakaderera kusungirirwa uye yakaderera viscosity, uye iyo yekunyudza inonamatira kune yakavharidzirwa workpiece, zvichikonzera kurasikirwa kwependi kushoma. Pendi inogona kushandiswa zvakanaka. Kunyanya mushure mekunge ultrafiltration teknolojia inoshandiswa kune electrophoresis, mubereko wepende uri pamusoro pe95%.

(5) DI mvura inoshandiswa sechinhu chinonyungudutsa mupendi ye electrophoretic (property: transparent, colorless liquid), iyo inochengetedza yakawanda organic solvents, uye hapana ngozi yekunyungudutsa chepfu uye kupisa, izvo zvinobvisa mhute yepende uye inovandudza mamiriro ekushanda evashandi. uye kusvibiswa kwezvakatipoteredza.

(6) Kuvandudza kupfava kwefirimu repende, kuderedza nguva yekupukuta uye kuderedza mutengo.

Nekuda kwemabhenefiti ari pamusoro eiyo electrophoretic coating, parizvino iri kushandiswa zvakanyanya, senge mota, matirakita, midziyo yemumba, midziyo yemagetsi, zvikamu zvemagetsi uye zvichingodaro.

Mukuwedzera, kutaridzika kwemavara cathodic electrophoretic pendi yakakodzera kupfekedzwa kwesimbi dzakasiyana-siyana uye alloys, zvakadai semhangura, sirivha, goridhe, tini, zinc alloy (Zn), simbi isina tsvina, nezvimwewo saka, magonhi ealuminium nemahwindo, zvishongo zvekugadzira, chiedza, nezvimwewo zvakashandiswa zvakanyanya. Kumwe kurapwa kwepamusoro kweblack electrophoresis ndeyekubvisa kunamatira kweiyo firimu yekuputira uye nepamusoro pechikamu chakavharwa, uye kuchenesa zvinhu zvinokanganisa aya maviri link.

Nguva yekutumira: Jul-08-2022