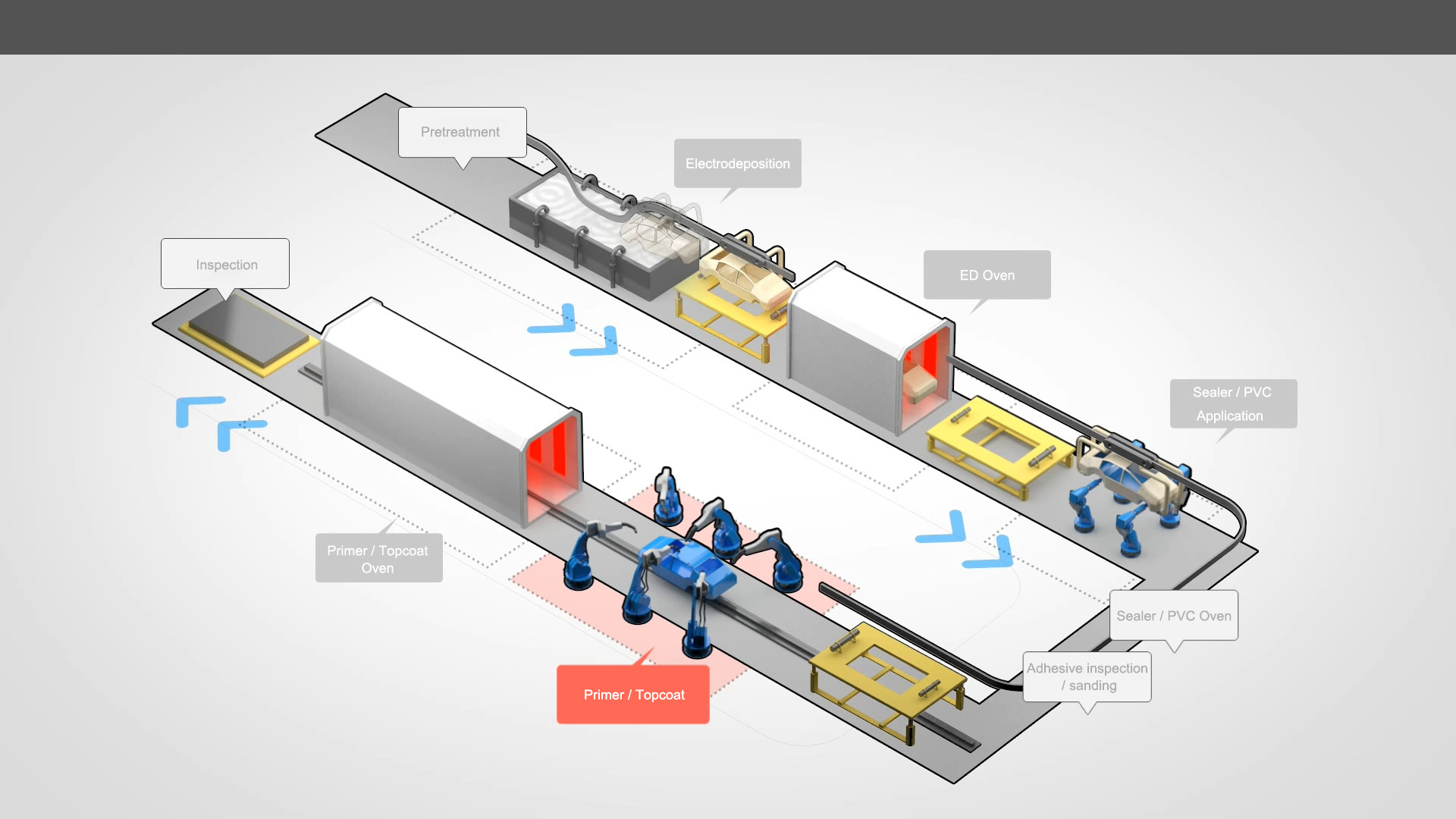

1. Pretreatment: Kuti ubvise mafuta asina kufanira, masara ewelding, uye tsvina kubva pamusoro peiyo mota inopinza muviri kubva kufekitori yemuviri, zinc phosphate film (3 ~ 5)㎛) inoshandiswa kumuviri wepamusoro kuti uwedzere kunamatira panguva yekuvhara pasi (electrodeposition). process. Nechinangwa chekudzivirira kwemuviri wemotokari.

- Pre-kuchenesa: Mushure mekuunganidza muviri, inogezwa nemvura isati yanyanya degreasing.

- Main degreasing: Inobvisa mafuta kubva mumuviri wemotokari.

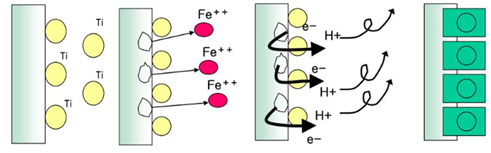

- Rinse conditional: Mushandi wekurapa ane titanium sechikamu chikuru, achigadzira nhamba huru yecolloid pamusoro pesimbi kuti iwedzere reactivity yekugadzira dense zinc phosphate film kuti ibudise makristasi akanaka uye akaonda.

- Zinc phosphate film: Zinc phosphate film inoshandiswa kusimbisa kunamatira kweiyo undercoat uye inhibit corrosion reaction.

1) Etching inotanga pane anode chikamu chesimbi simbi mune coating solution

2) Zvichienderana nekuora ikozvino, cations inopedzwa pa cathode, uye pH ye interface inokwira.

3) Colloid pamusoro pepamusoro inova nucleus uye inopenya

- Mvura yakaoma ovheni: Maitiro ekubvisa zvachose hunyoro kubva kune substrate mushure mekutanga kurapwa kwapera.

※ Kutamisa kupisa uye kuomesa mukuomeswa kwemaoko

Mushure mekuvhara muviri nezinc phosphate film (), gezai nemvura uye muome nemaoko. Kuomeswa nemaoko inzira yekubvisa zvachose hunyoro kubva pachinhu chichaputirwa uyezve kuita inotevera kupenda. Simudza tembiricha kuti upfutidze hunyoro kuburikidza nekutamisa kupisa. Kuomesa (evaporation) chiitiko chinoitika kana tembiricha yenzvimbo yakasimba pakubata yakadzikira pane panovira uye mhepo yemuchadenga yakadzikira pane mhepo yemhute. kuchinja kwechikamu kuchaitika. Tembiricha uye nguva inodiwa pachoto chekuomeswa nemaoko zvinosiyana zvichienderana nechinhu, ukobvu, uye chimiro chechinhu chichaputirwa. Kazhinji, maminetsi gumi pa120 ~ 150 ℃ zvakajairika, uye chikonzero chekusimudza tembiricha ndeyekuwedzera mhute yekumanikidza yemvura inoenderana neicho tembiricha uye kuoma nekukurumidza nekupa yakawanda kupisa simba. Panguva ino, hapafanirwe kuve nesimbi kana kemikari shanduko nekuda kwekushisa.

1,Electrodeposition process: Nzira yekugadzira firimu rekuvhara mukati / kunze kwemuviri wemotokari nekushandisa electrophoresis kuburikidza nemagetsi mushure mekunyudza muviri wemotokari mupendi ye electrodeposition, nechinangwa chekudzivirira kuparara kwemuviri wemotokari.

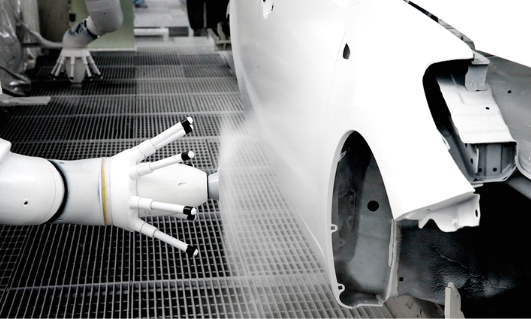

- Electrodeposition: Electrodeposition pendi inzira yekupenda umo pendi inosungirirwa nemagetsi nekunyudza muviri wemota mupendi mhinduro uye inoyerera anode kana cathode kuburikidza nemuviri wemotokari. Zvisinei, inzira yakakodzera kugadzirwa kwemazhinji, uye zvakaoma kupendesa kana firimu rekuputira rabatanidzwa uye magetsi asingayereri.

- DI sukurudza

- Electrodeposition Drying Furnace: Kune cationic electrodeposition coatings, iyo inonyanya kushandiswa, kupisa-kuomesa moto kunoshandiswa nekuti iyo firimu yakaiswa pamusoro inokwenenzverwa nekupisa kwemvura ne thermal crosslinking (thermal curing) reaction. Tembiricha nenguva inodiwa pakupisa inosiyana zvichienderana nechinhu, ukobvu, uye chimiro chechinhu chichaputirwa. Muchiitiko chechinhu chakatetepa chakavharwa, tembiricha yepasi i200-210 ° C uye tembiricha yechoto inorapa i210-230 ° C, uye nguva yekudziya inowanzoita maminetsi makumi maviri-makumi matatu pakukwana kwemaminetsi gumi kana kupfuura kuti nguva yekupisa yechinhu chifukidzwe uye 200-210 ° C kubata nguva.

- Electrodeposition polishing: Geya zvakakasharara uye zvakabudikira mativi epasi kuti zvitsvedzerere.

2、Halfway Paint: Iyi ndiyo nzira yekushandisa pendi, iyo inowanzonzi primer. Inochenesa nzvimbo kuitira kuti jasi repamusoro ribatanidze zvakanaka uye rinoita basa rekuvandudza kusagadzikana kwekuora. Ndinoshandisa ruvara rwakasiyana zvishoma rwepakati kuti rifanane neruvara rwejasi repamusoro.

- Intermediate maitiro

- Medium kuomesa choto

3, pamusoro pejasi: Maitiro ekuisa iyo inoonekwa mota ruvara uye kupedzisa nependi yakajeka. Munguva pfupi yapfuura, nekuda kwemitemo yezvakatipoteredza, nezvimwewo, eco-friendly paints (yakaderera zvinhu zvinyorwa zvinyorwa) zvishoma nezvishoma zvinoshandiswa. Pachena mushure mejasi repamusoro

- pamusoro pejasi maitiro

- Topcoat kuomesa choto

※ Kupisa kupisa mu electrodeposition / yepakati / yepamusoro jasi kudziyisa uye kuomesa choto

Muchoto chekuomesa, kupisa kunotamirwa kunzvimbo yakapendwa nenzira mbiri.

Convection: Kuti usvike nyore nyore kupisa kwekushisa kwekupisa kwefirimu yekuputira, mhepo inokurumidza kuyerera inodikanwa, uye high speed convection inowanikwa nekutenderera mhepo inopisa muchoto chekuomesa pamhepo inomhanya (forced convection).

Radiant kupisa: Rusvingo runodziiswa kusvika mazana akati wandei madhigirii pamusoro petembiricha yekurapisa yefirimu yekuputira muchoto chakagadzirirwa kuomesa, uye kupisa kunopisa kunopfuudzwa kunzvimbo yakapendwa nenzira imwechete iyo chitofu chinodziya muviri.

Nguva yekutumira: Nov-08-2022