Surley muunganidzwa wepretreatment uye electrophoresis maitiro Spray booth ovheni hurongwa hwekufambisa shower test bhenji tekinoroji yekuchengetedza kwezvakatipoteredza Accessories workstationgadzira zvese muchitoro chimwe.

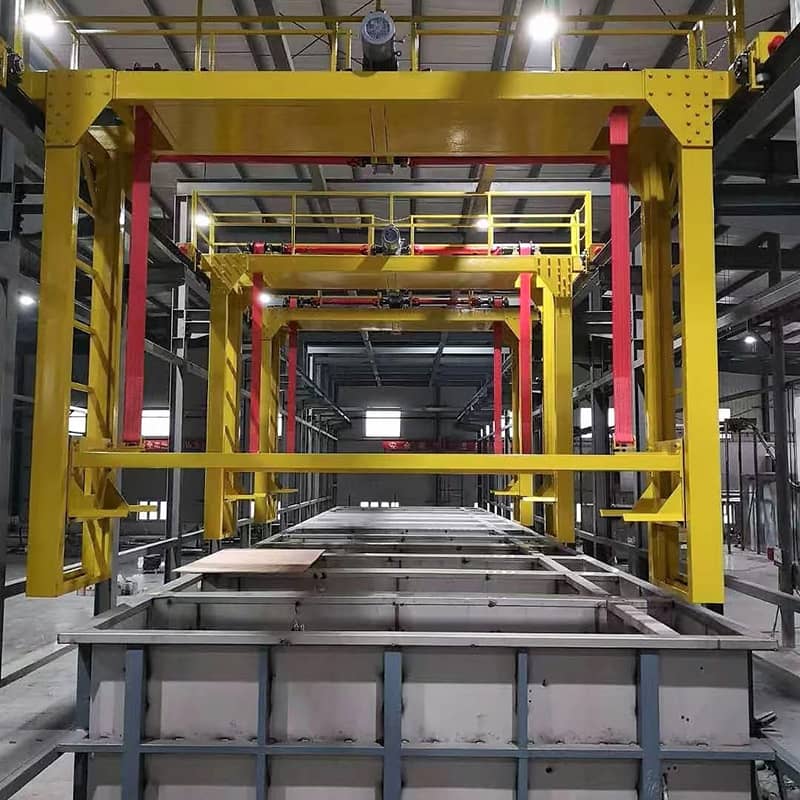

Pretreatment uye electrocoating process

Product Description

Zvinhu zvakasiyana-siyana uye zvigadzirwa zvavo mukugadzirisa, kutakura, kuchengetedza, nzvimbo yaro iri nyore kugadzira kana

namatira kunze kwenyika, senge machining burr, oxide ganda, mafuta, nezvimwewo, izvi zvinosvibisa zvepamusoro zvinokanganisa kubatanidzwa kwejasi uye kusimba kwekubatanidza nematrix.Coating pretreatment of the mainChinangwa ndechekubvisa zvinhu izvi uye kuita yakakodzera pamusoro pemakemikari shanduko kuti ipe yakakodzeraKupfekedza zvinodiwa zveiyo substrate, kuitira kuwedzera kunamatira kwefirimu, kurebesa hupenyu hwesevhisi yefirimu, Ipa kutamba kwakazara kune inodzivirira. mhedzisiro uye yekushongedza mhedzisiro yekupfeka.

Naizvozvo, pfapfaidza zvirimo usati wagadzirisa.Zvinonyanya kusanganisira zvinotevera zvinhu:

Phosphate firimu musimboti

firimu rephosphating rakakwanisa kupa hwaro hwakakodzera kwazvo hwekuputira pendi, nekuda kweinotevera mhedzisiro:

1) Inopa yakachena, yunifomu, isina girisi pasi pahwaro hwekupedza degreasing

2) inosimudzira kunamatira kweiyo organic film kune substrate nekuda kwekuita kwemuviri uye kemikari Hazvinetse kunzwisisa kuti iyo porous chimiro chephosphating firimu inowedzera nzvimbo yepasi peiyo substrate, kuitira kuti nzvimbo yekubatanidza pakati pezviviri iwedzere zvinoenderana, uye iyo inobatsira mutual permeability pakati pezvikamu zviviri zvefirimu inogadzirwa.Panguva imwecheteyo, kusangana kwemakemikari pakati peunsaturated resin uye phosphate crystal inowedzerawo simba rayo rekusunga.

3) kupa yakagadzikana isina-conductive isolation layer, kamwechete iyo yekuputira kukanganisa, ine basa rekuvharisa corrosion inhibition, kunyanya kune anode incision Pfungwa yekutanga inowanzoregeredzwa Chete kusvika kune yakanakisa yemafuta kuumba inogutsa phosphating firimu So. iyo phosphating firimu pachayo ndiyo yakanyanya intuitive mhedzisiro yepretreatment tekinoroji yeakanyanya kuvimbika kuzviongorora.

Product Details